Nidaamyada qaboojinta nitrogen dareeraha ah ayaa si weyn loogu isticmaalaa semiconductor & warshadaha chip, oo ay ku jiraan habka,

- Tignoolajiyada Molecular Beam Epitaxy (MBE)

- Tijaabada chip-ka kadib xirmada COB

Alaabooyinka La Xiriira

EPITAXY BEAM MOLECULAR

Tignoolajiyada Molecular Beam Epitaxy (MBE) waxaa la sameeyay 1950-meeyadii si loogu diyaariyo agabka filim khafiif ah oo semiconductor ah iyadoo la adeegsanayo tignoolajiyada uumiga uumiga. Iyada oo la horumarinayo tignoolajiyada vacuum ultra-sare, adeegsiga tignoolajiyada ayaa la fidiyay goobta sayniska semiconductor.

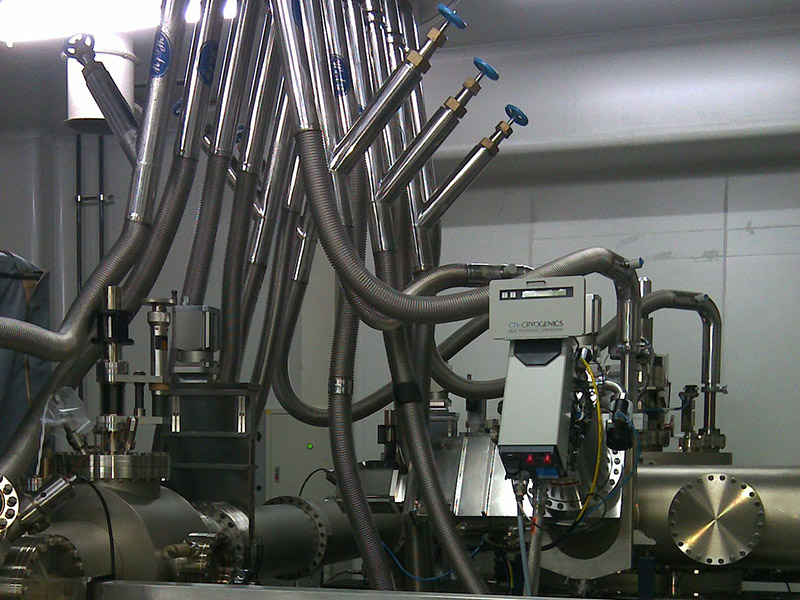

HL waxay ogaatay baahida MBE nidaamka qaboojinta nitrogen dareere ah, habaysan laf-dhabarta farsamada si ay si guul leh u horumariyaan nidaamka qaboojinta nitrogen dareere ah MBE gaar ah ee tignoolajiyada MBE iyo set dhamaystiran oo ah nidaamka dhuumaha dahaaran vacuum, kaas oo loo adeegsaday shirkado badan, jaamacadaha iyo machadyada cilmi-baarista. .

Dhibaatooyinka caadiga ah ee warshadaha semiconductor & chip waxaa ka mid ah,

- Cadaadiska Nitrogen dareeraha ah ee Qalabka Terminal (MBE). Ka-hortagga culeyska xad-dhaafka ah ee ka yimaada Qalabka Terminalka (MBE).

- Xakamaynta Dareeraha Cryogenic ee Kala Duwan

- Heerkulka Nitrogen-ka dareeraha ah ee Qalabka Terminalka

- Qadar Macquul ah oo ah Gaaska Cryogenic ka sii daayo

- (Si Toos ah) Beddelka Xadhkaha Weyn iyo Laanta

- Hagaajinta Cadaadiska ( Yaraynta ) iyo Deganaanshaha VIP-da

- Nadiifinta wasakhda suurtogalka ah iyo hadhaaga barafka ee haanta

- Wakhtiga Buuxinta Qalabka dareeraha ee Terminalka

- Dhuumaha Precooling

- Iska caabinta dareeraha ee Nidaamka VIP

- Xakamaynta luminta Nitrogen-ka dareeraha ah inta lagu jiro Adeegga Joogtada ah ee Nidaamka

HL's Vacuum Insulated Pipe (VIP) waxaa loo dhisay ASME B31.3 Koodhka Tuubooyinka Cadaadiska sida caadiga ah. Khibrada injineernimada iyo awoodda xakamaynta tayada si loo hubiyo waxtarka iyo waxtarka kharashka ee warshadda macaamiisha.

Xalka

Qalabka HL Cryogenic Equipment waxay siisaa macaamiisha Nidaamka Tuubbooyinka Daahsoon ee Vacuum si ay u buuxiyaan shuruudaha iyo shuruudaha semiconductor & chips:

1. Nidaamka Maareynta Tayada: ASME B31.3 Xeerka Tuubbooyinka Cadaadiska.

2.A Wajiga Gaarka ah ee Kala-soocida oo leh Multiple Cryogenic Liquid Inlet iyo Outlet oo leh shaqeyn toos ah oo xakameyn ah ayaa buuxisa shuruudaha gaaska qiiqa, nitrogen dareeraha dib loo warshadeeyay iyo heerkulka nitrogen dareeraha ah.

3.Naqshadaynta qiiqa ku filan iyo wakhtiga ku habboon waxay hubisaa in qalabka terminalku uu had iyo jeer ku shaqeeyo qiimaha cadaadiska loogu talagalay.

4.Gaas-dareere Barrier waxaa lagu dhejiyaa tuubada VI toosan ee dhamaadka dhuumaha VI. Gaasta-dareere Barrier waxay isticmaashaa mabda'a shaabadda gaaska si ay u xannibto kulaylka dhamaadka dhuumaha VI ee tuubooyinka VI, oo si wax ku ool ah u yareeya luminta nitrogen dareeraha ah inta lagu jiro adeegga joogtada ah ee nidaamka.

5.VI tuubbooyinka uu xakameeyo Vacuum Insulated Valve (VIV) Taxane: oo ay ku jiraan Vacuum Insulated (Pneumatic) Shut-off Valve, Vacuum Insulated Check Valve, Vacuum Insulated Valve iwm. Noocyo kala duwan oo VIV ah ayaa la isku dari karaa si loo xakameeyo VIP-da sida loo baahan yahay. VIV waxaa lagu dhex daray VIP prefabrication ee soo saaraha, iyada oo aan lahayn daawaynta goobta. Unugga shaabadda ee VIV si fudud ayaa loo beddeli karaa. (HL waxay aqbashaa summada waalka loo yaqaan 'cryptoogenic valve valve' ee ay macmiishadu u qoondeeyeen, ka dibna waxay HL ka samaysaa vacuum valves-dahaaran

6.Cleanliness, haddii ay jiraan shuruudo dheeraad ah oo loogu talagalay nadiifinta dusha sare ee tuubada gudaha. Waxaa la soo jeediyay in macaamiishu ay doortaan BA ama EP tuubooyinka birta aan daahin ee VIP ahaan tuubooyinka gudaha si loo sii yareeyo daadinta birta.

7.Vacuum Insulated Filter: Ka nadiifi wasakhaha suurtagalka ah iyo hadhaaga barafka haanta.

8.Ka dib dhowr maalmood ama ka badan xiritaanka ama dayactirka, waxaa aad loogu baahan yahay in la qaboojiyo VI Tuubooyinka iyo qalabka terminal ka hor inta dareere cryogenic la gelin, si looga fogaado slag ka dib markii dareere cryogenic si toos ah u galo VI Tuubooyinka iyo qalabka terminal. Shaqada qaboojinta ka hor waa in lagu tixgeliyo naqshad ahaan. Waxay siisaa ilaalin ka wanaagsan qalabka terminaalka iyo VI qalabka taageerada tuubooyinka sida valves.

9.Ku habboon labadaba Nidaamka Tuubbooyinka Dahaarka ah ee Dhaqdhaqaaqa iyo Joogtada ah (Flexible).

10.Dynamic Vacuum Insulated (Flexible) Nidaamka Tuubooyinka: Ka kooban VI tuubooyinka dabacsan iyo / ama VI tuubooyinka, Jumper Hoses, Vacuum Insulated Valve System, Wajiga Kala-soocida iyo Nidaamka Mashiinnada Vacuum Vakuum ee Firfircoon (oo ay ku jiraan bambooyin vacuum ah, valves solenoid iyo gauges vacuum iwm. ). Dhererka hal VI Flexible Hose waxaa loo habeyn karaa iyadoo loo eegayo shuruudaha isticmaalaha.

11.Noocyo kala duwan oo isku xidhan: Vacuum Bayone Connection (VBC) Nooca iyo xidhiidhka alxanka waa la dooran karaa. Nooca VBC uma baahna daaweyn dahaaran oo goobta taal.